Solutions for highest demands

Sample Gas coolers from AGT are solutions for highest demands on the Sample Gas Quality. With optional components (e.g. pre-separator, filter, flow meter, acid metering, humidity monitor, gas pumps) the gas cooler can be configured to become a compact sample gas conditioner system.

For the cooling, both specifically designed compressor and Peltier (thermo electric)- operated solutions are available. The selecting of the heat exchanger, the “heart” of a Sample Gas Cooler, a wide range of geometries and materials are available depending on the requirement of the application: whether as a simple Sample Gas Cooler for drying a probe sample stream or as a wash-out-optimized heat exchanger within a Sample gas conditioner system for emission measurements – the wide range of products offers the right configuration.

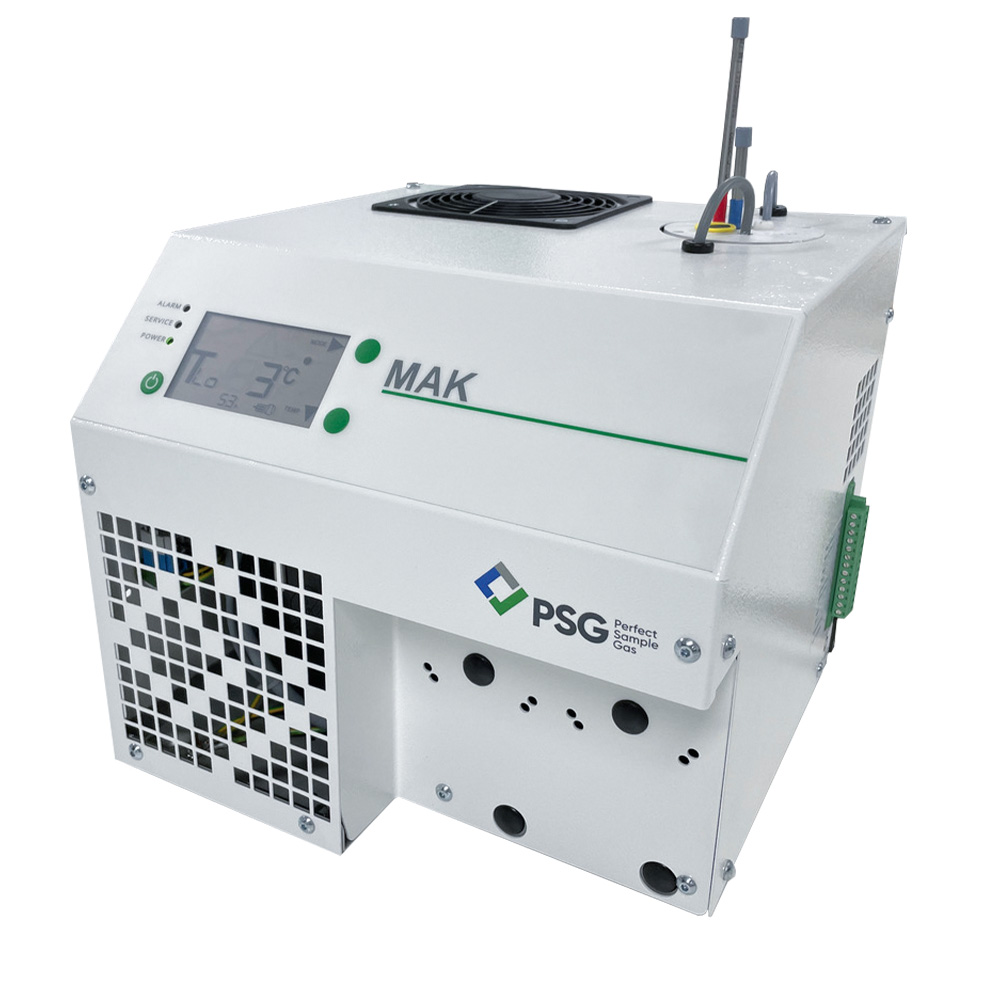

MAK sample gas cooler / preparation:

The MAK product range stands for compressor or Peltier (Thermo electric) -operated Sample Gas Coolers that meet the highest requirements in terms of wash-out effects as well as a constant and low outlet dew point. In addition, both MAK 10 and the newly developed MAK 20 offer, in addition to the configuration of 1-4 gas paths, the option of integrating all components that are required for compact Sample Gas Conditioner.

BCR all-round compressor gas cooler

The BCR series includes compressor Sample Gas Cooler that are focused on high flow rates, thus enabling fast measurements and can be used in ATEX areas.